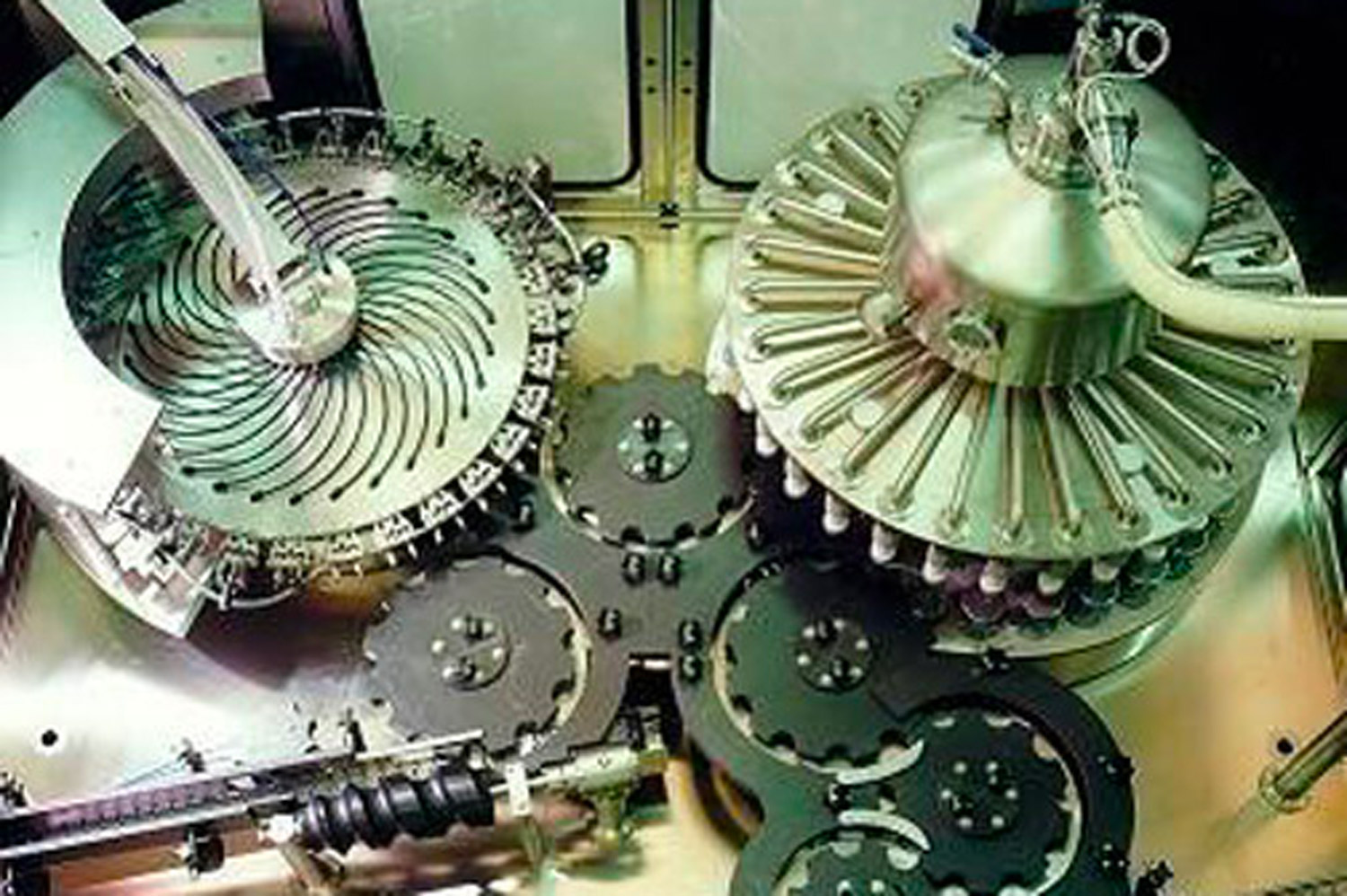

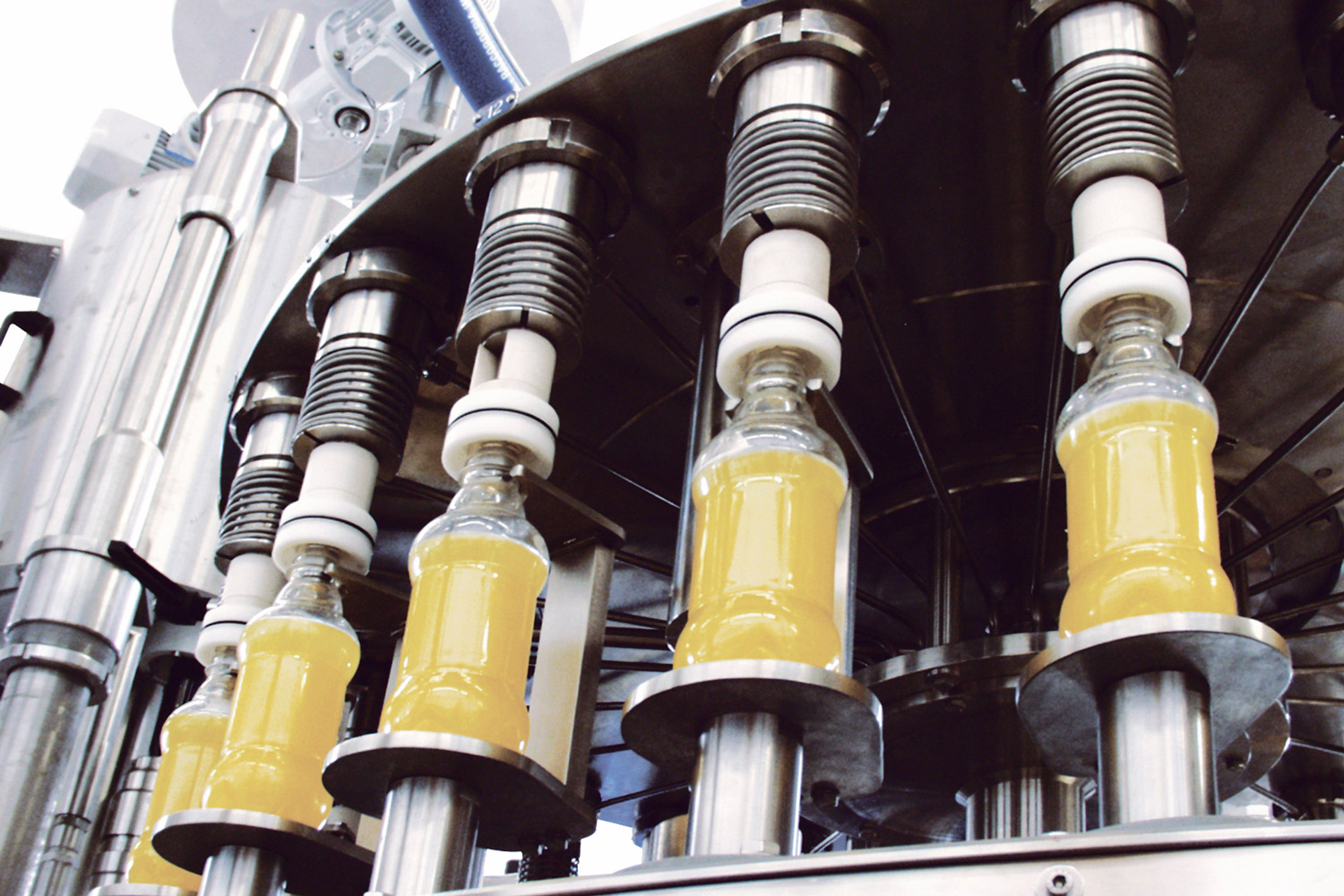

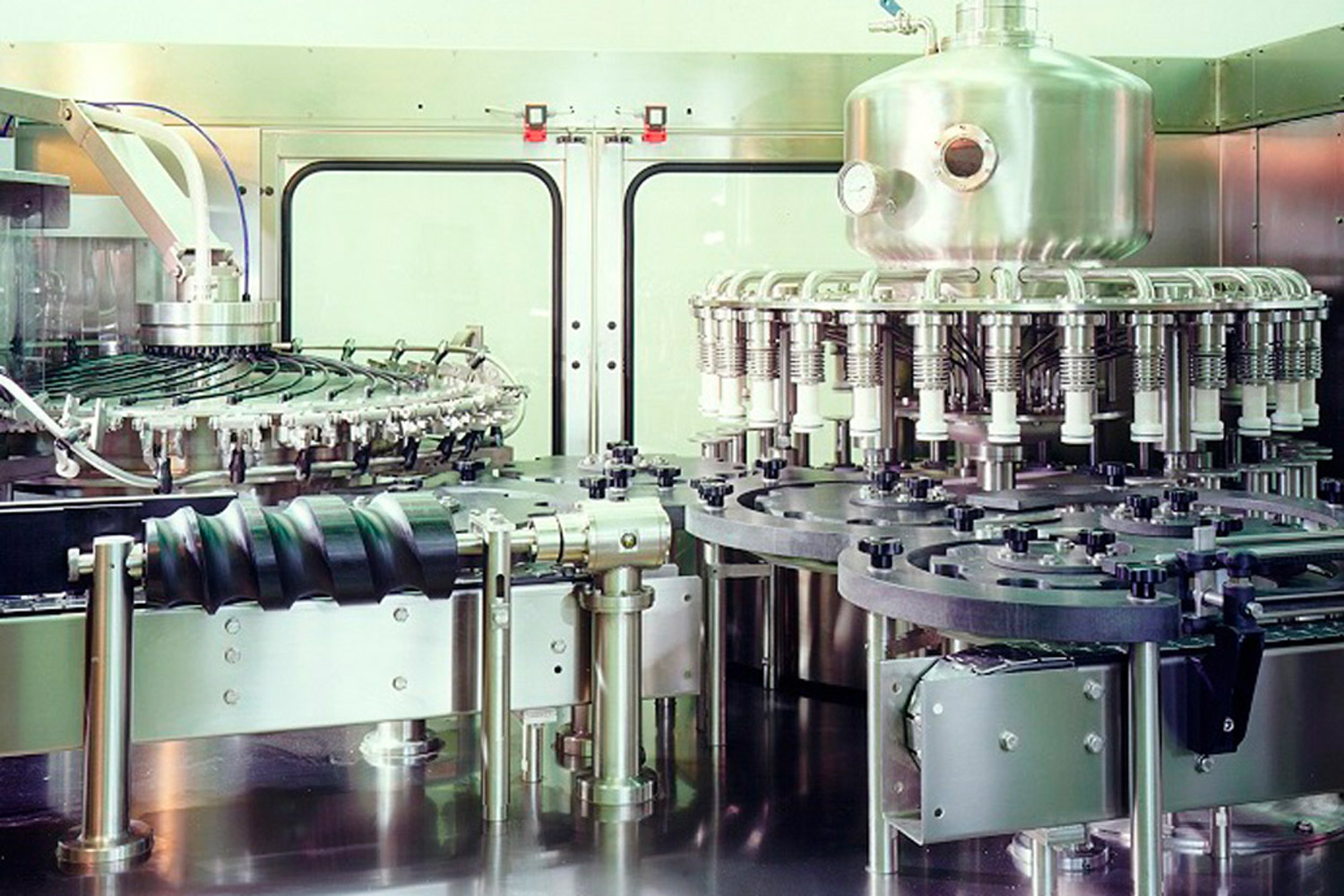

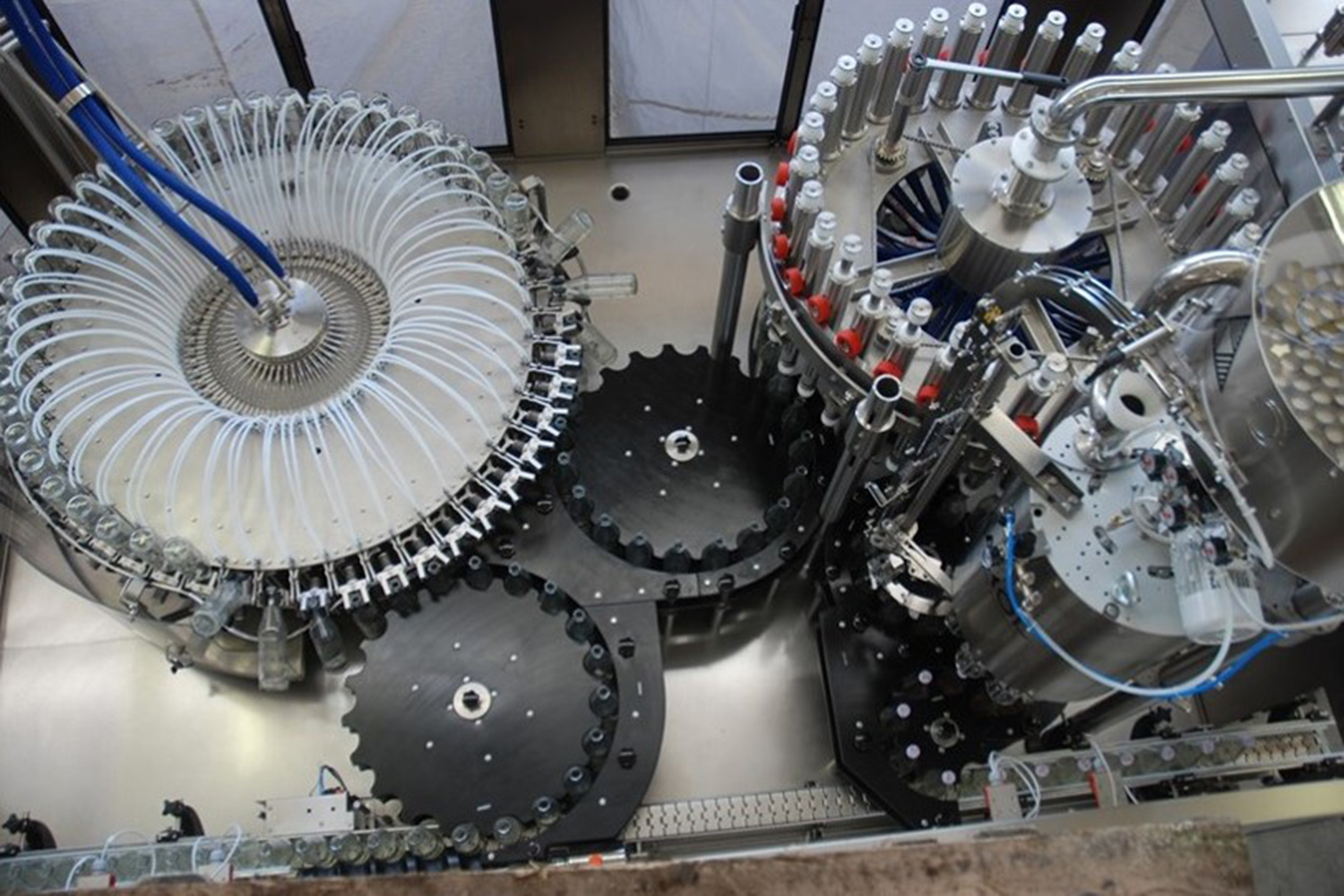

Hotjet EP is our filler for juices, tea and isotonic drinks featuring the control of the product recirculation, thanks to electro-pneumatic devices . Due to its characteristics, it is particularly suitable for hot filling (up to 90°C) of low and medium viscosity products in glass bottles and in PET resistant to high temperatures. It is used for medium and long term storage at room temperature. A special pneumatic device installed on each filling valve allows an accurate control of the recycled product.

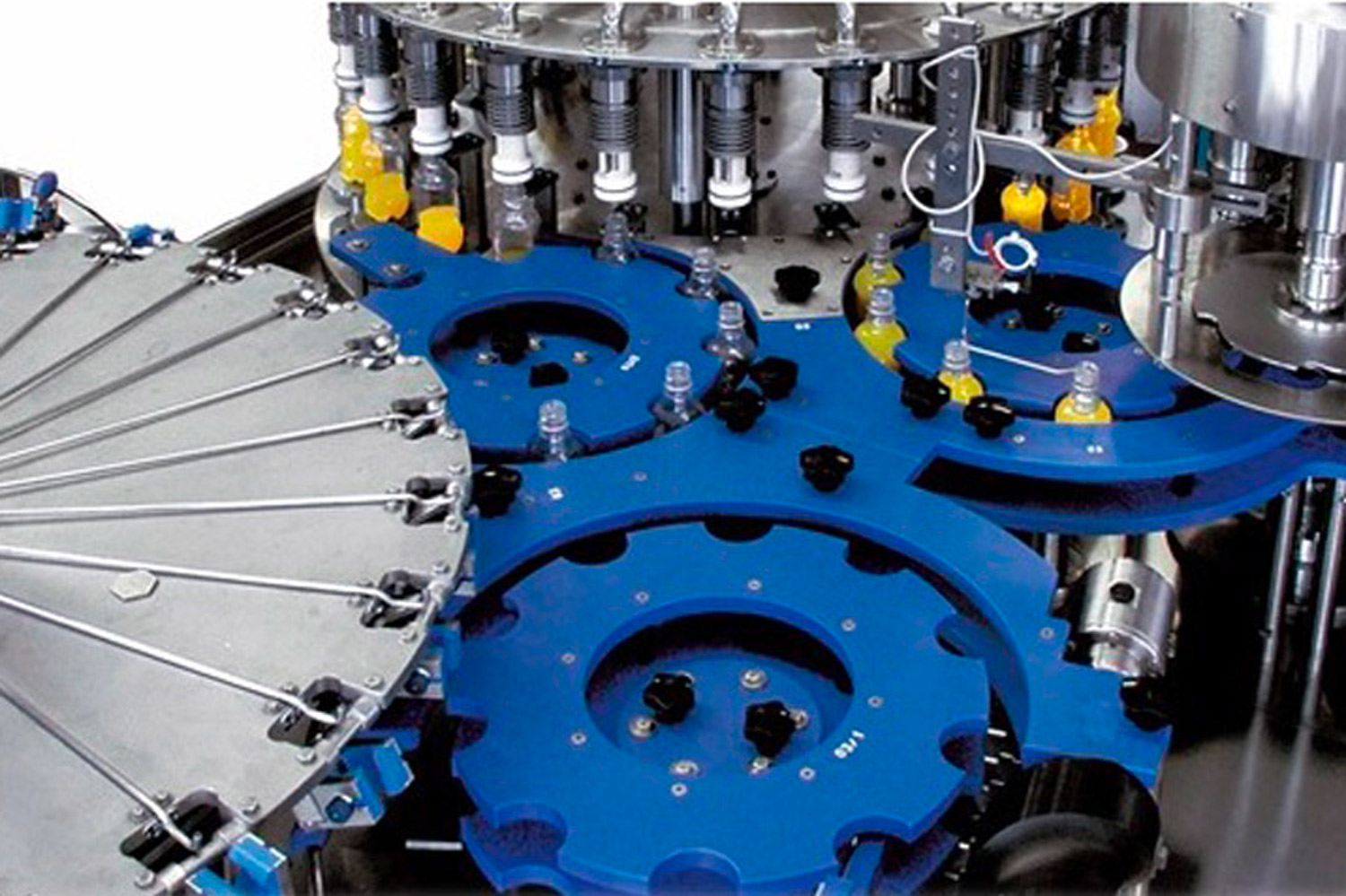

The machine is easily adjustable in height to handle different formats; In the case of PET containers, the bottle transfer is made by neck handling system.

ADVANTAGES

- Constant control of the filling temperature

- Accuracy in filling levels

- Controlled product recirculation (also in the bottle) and adjustable according to the format in use

- Extreme ease of use and low maintenance requirements

- Possibility of “brim full” filling

FRUIT JUICE, TEA, SPORTS DRINKS

- Production: 4.000 ÷ 60.000 bph

- n ° valves: 20 ÷ 100

- PET-Glass treatable bottles

- Treatable bottles (h) 140 ÷ 340

- Treatable bottles (Ø) 48 ÷ 115

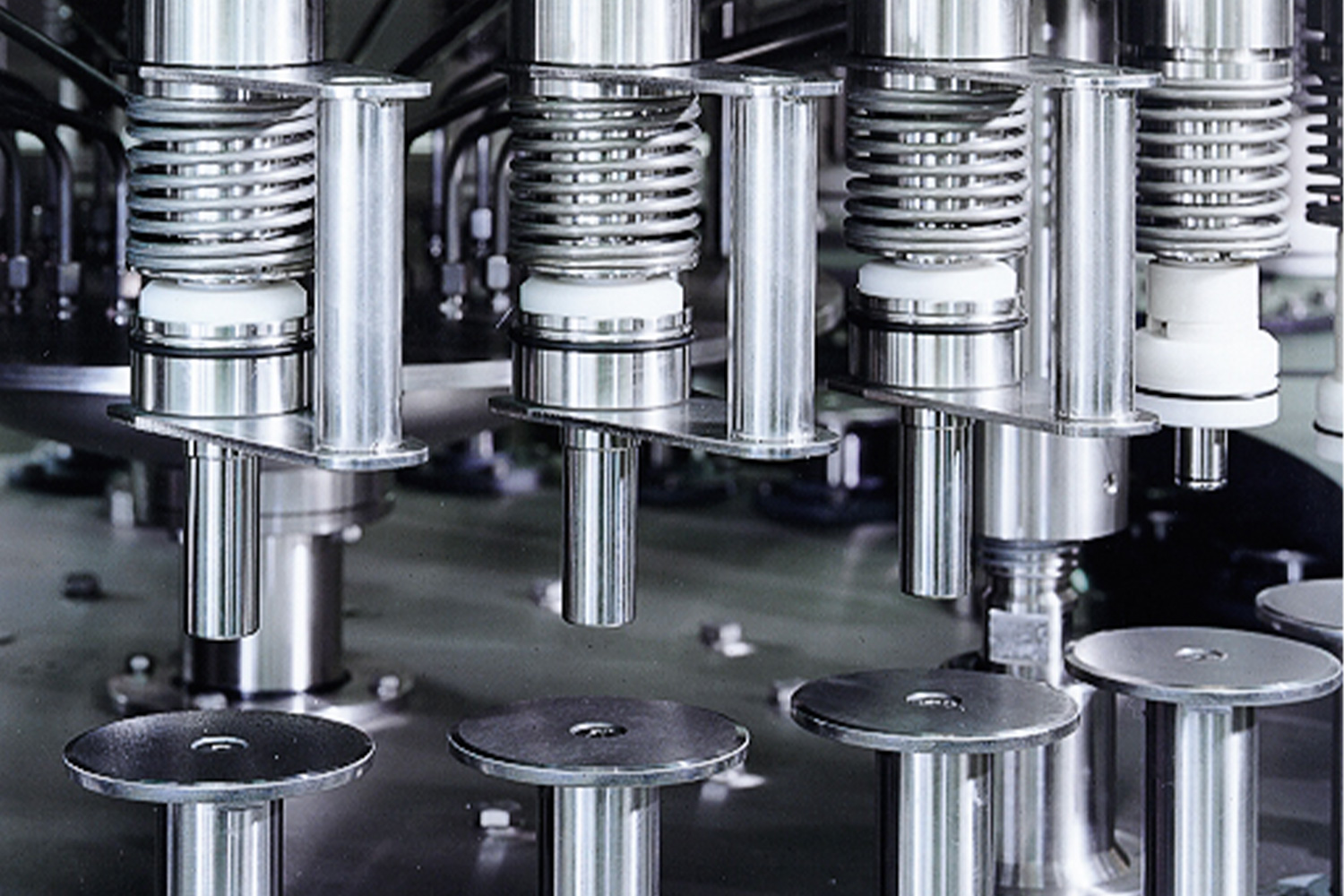

- Parts in contact with the product in SS 304

- Touch Screen operator panel

- Dummy bottles for sanitization

- Base in SS 304

- SS 304 and Drainable bas

- Automatic centralized lubrication

- Parts in contact with the product in SS 316L

- Teleassistance

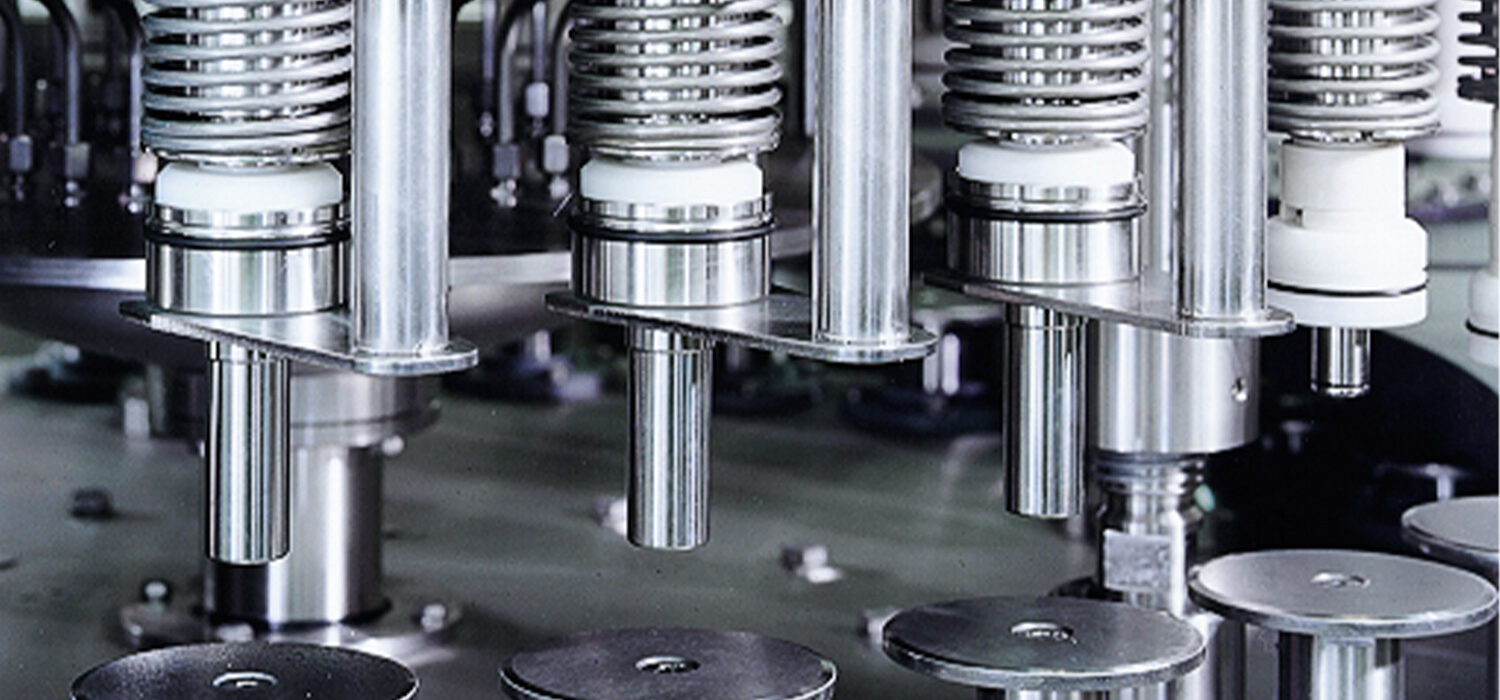

The filling takes place by gravity, and can be assisted by slight vacuum. Product delivery occurs only if the bottle is present and if the pneumatic opening device is activated; after filling, the product present in the vent tube ends up in the recycling system and return to the recycled product tank.

It is electro-pneumatically controlled and it is used to keep the filling temperature and the entire circuit constant. The HOTJET valve also allows the recirculation of the product in the bottle. The electro-pneumatic recirculation system allows to keep the recycled quantity values within the limits required by current industry standards.

The feed and recirculation tanks, valves and other parts in contact with the product are mirror polished and slightly inclined to avoid dirt residues and facilitate washing and drainage. These parts can be washed and sanitized with liquid, cold or hot solutions.

Fill in the form to receive all the details you need about all Melegari Technology bottling machinery

Discover more products of

Promec Group

Leader in bottle handling, cleaning and sterilization sector.

Promec srl

New intelligent blow molding machines, for a sustainable choice.

Blowtec