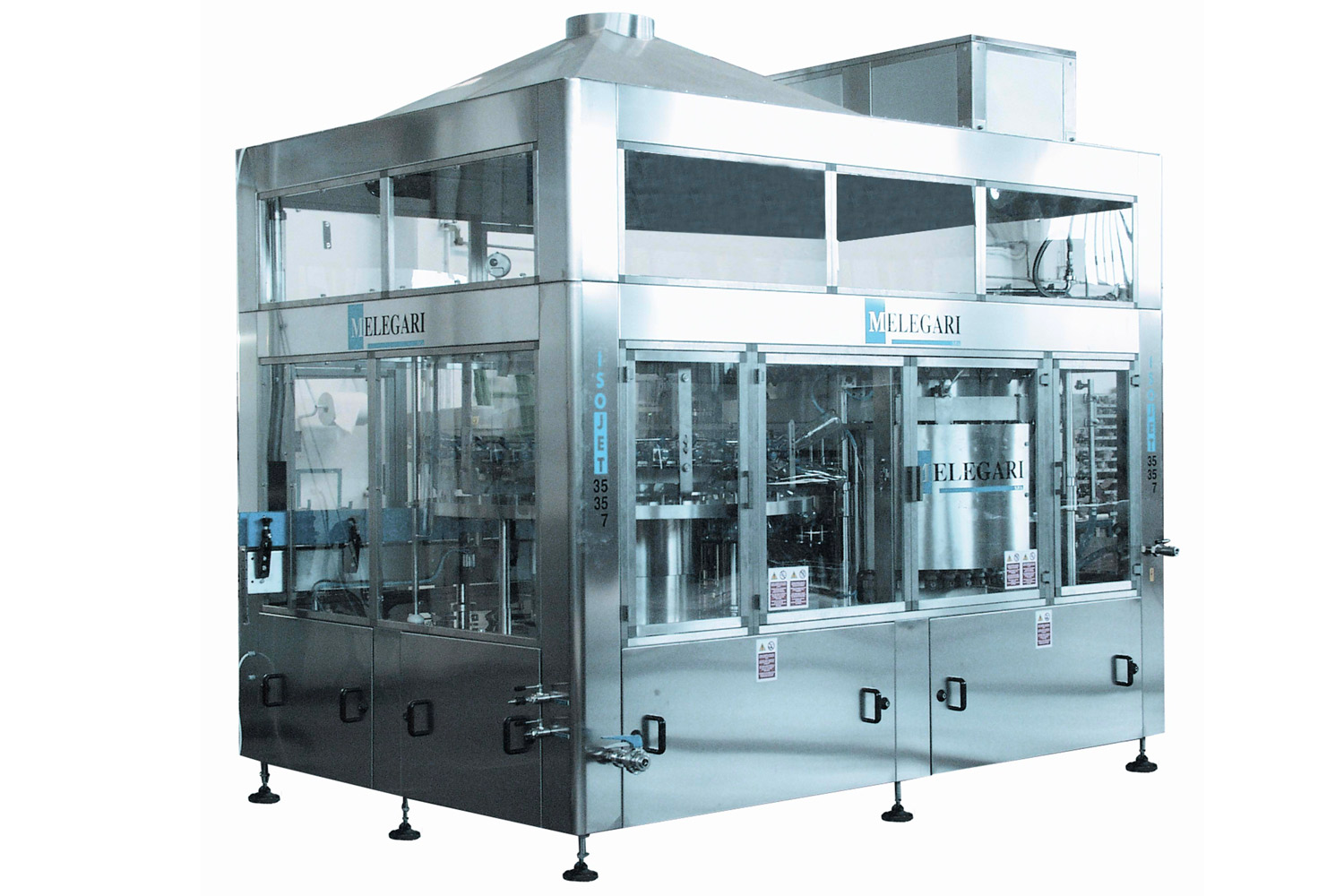

Isojet EP, our isobaric filler equipped with electro-pneumatic control of the various phases of the process, is ideal for filling carbonated and non-carbonated water and soft drinks, in glass or plastic bottles and is the result of Melegari Technology gained thanks to years of experience in the specific sector extreme reliability and ease of management, a facilitated change over, simple and quick maintenance, a fully automatic sanitization system, a “touch screen” operator panel for careful control of the production and sanitization cycles, are some of the important qualities of this machine.

ADVANTAGES

- Extreme flexibility in handling different bottles and products thanks to the electro-pneumatic management of the pressurization, filling and degassing phases.

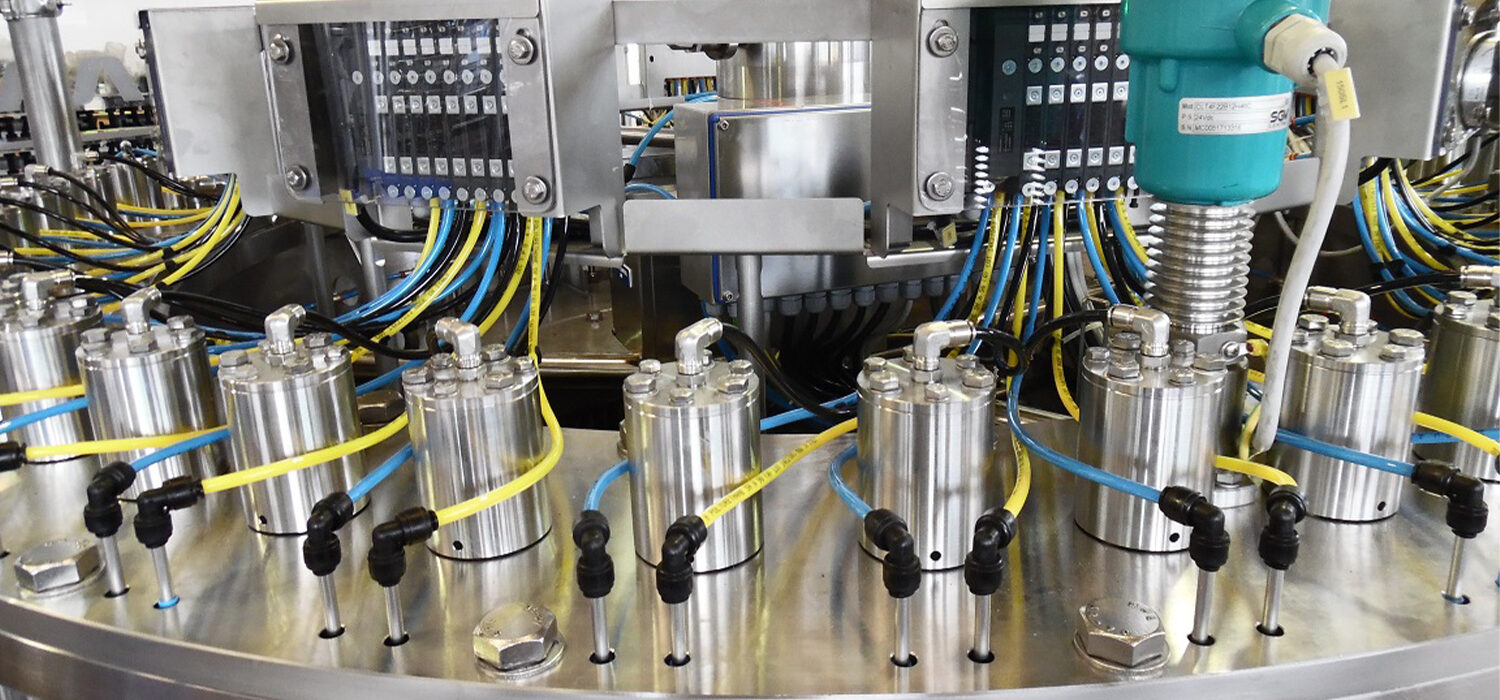

- No external control elements installed on the filling carousel.

- High performance and extreme accuracy in bottle level precision

- Ease of use and low maintenance

- High reliability

- Possibility of filling flat products

CARBONATED WATER

- Production : 2.500 ÷ 72.000 bph

- n ° valves: 15 ÷ 140

- PET-Glass treatable bottles

- Treatable bottles (h) 140 ÷ 340

- Treatable bottles (Ø) 48 ÷ 115

- Parts in contact with the product in SS 304

- Touch Screen operator panel

- Dummy bottles for sanitization

- Base in SS 304

- SS 304 and Drainable base

- Automatic centralized lubrication

- Parts in contact with the product in SS 316L

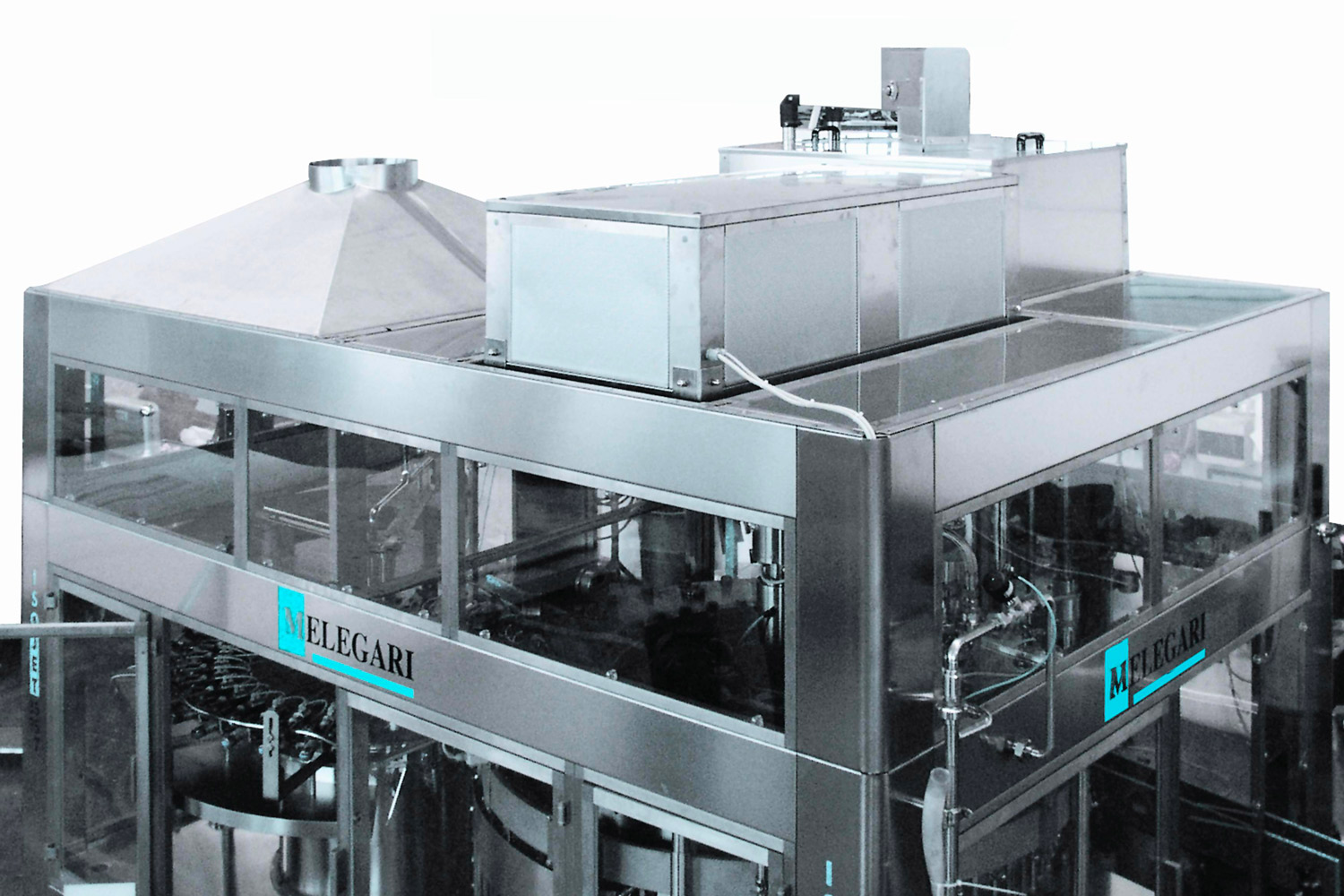

- Laminar flow cabin with positive pressure and HEPA filters

- Remote assistance

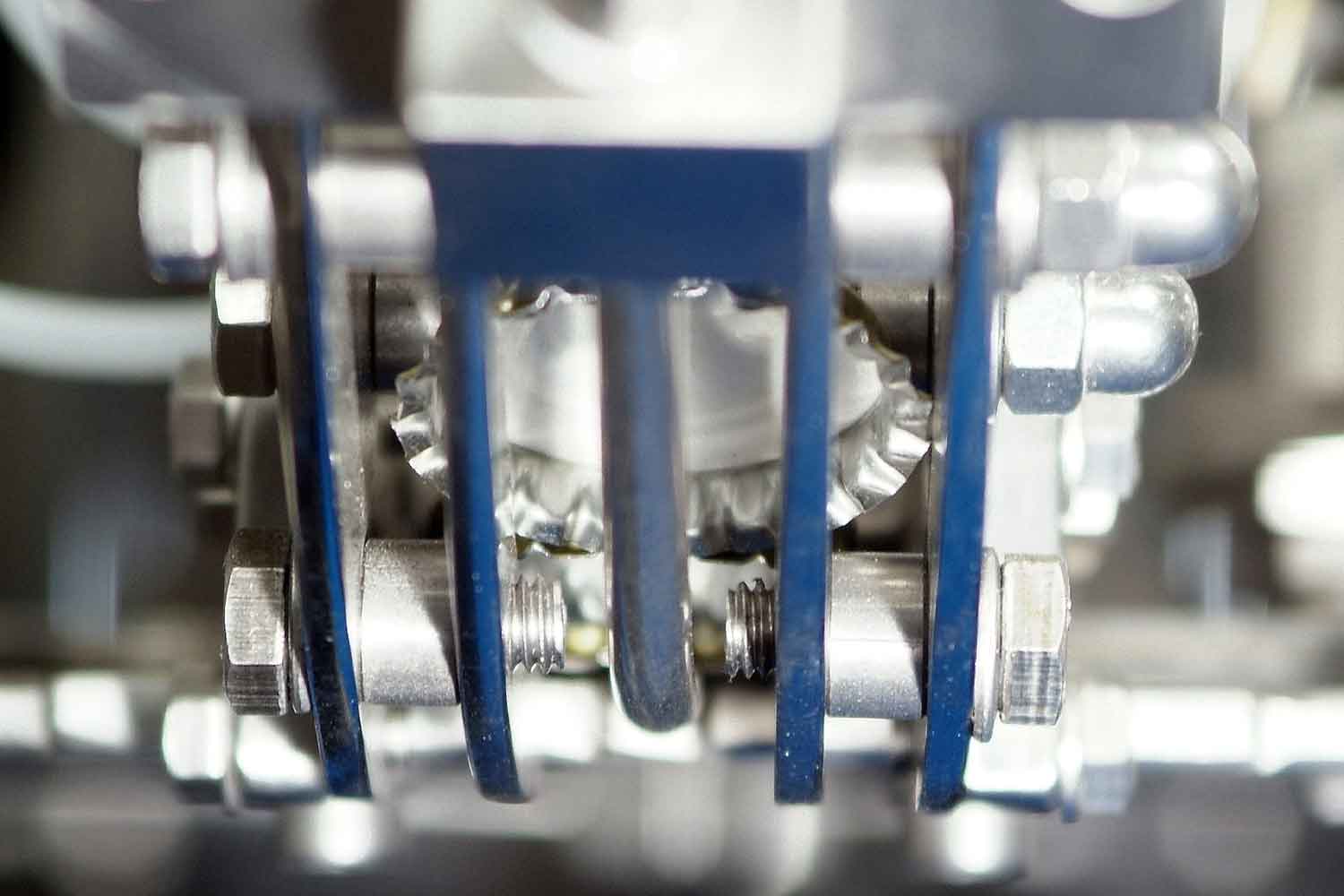

Filling begins when the pressure balance between tank and bottle is reached thanks to the activation of a pneumatic CO2 injection valve. The filling stops when the liquid reaches the air return spout; the valve can therefore be closed. Subsequently a further pneumatic device controls the decompression phase to guarantee absence of turbulence and foam when the bottle comes out of the machine.

The tank, the valves and all the parts in contact with the product are mirror polished and slightly inclined to avoid dirt residues and facilitate washing and drainage, which can be carried out with liquid, cold and hot solutions. Sanitization is controlled automatically by the machine control program and is activated by electro-pneumatic devices.

Fill in the form to receive all the details you need about all Melegari Technology bottling machinery

Discover more products of

Promec Group

Leader in bottle handling, cleaning and sterilization sector.

Promec srl

New intelligent blow molding machines, for a sustainable choice.

Blowtec