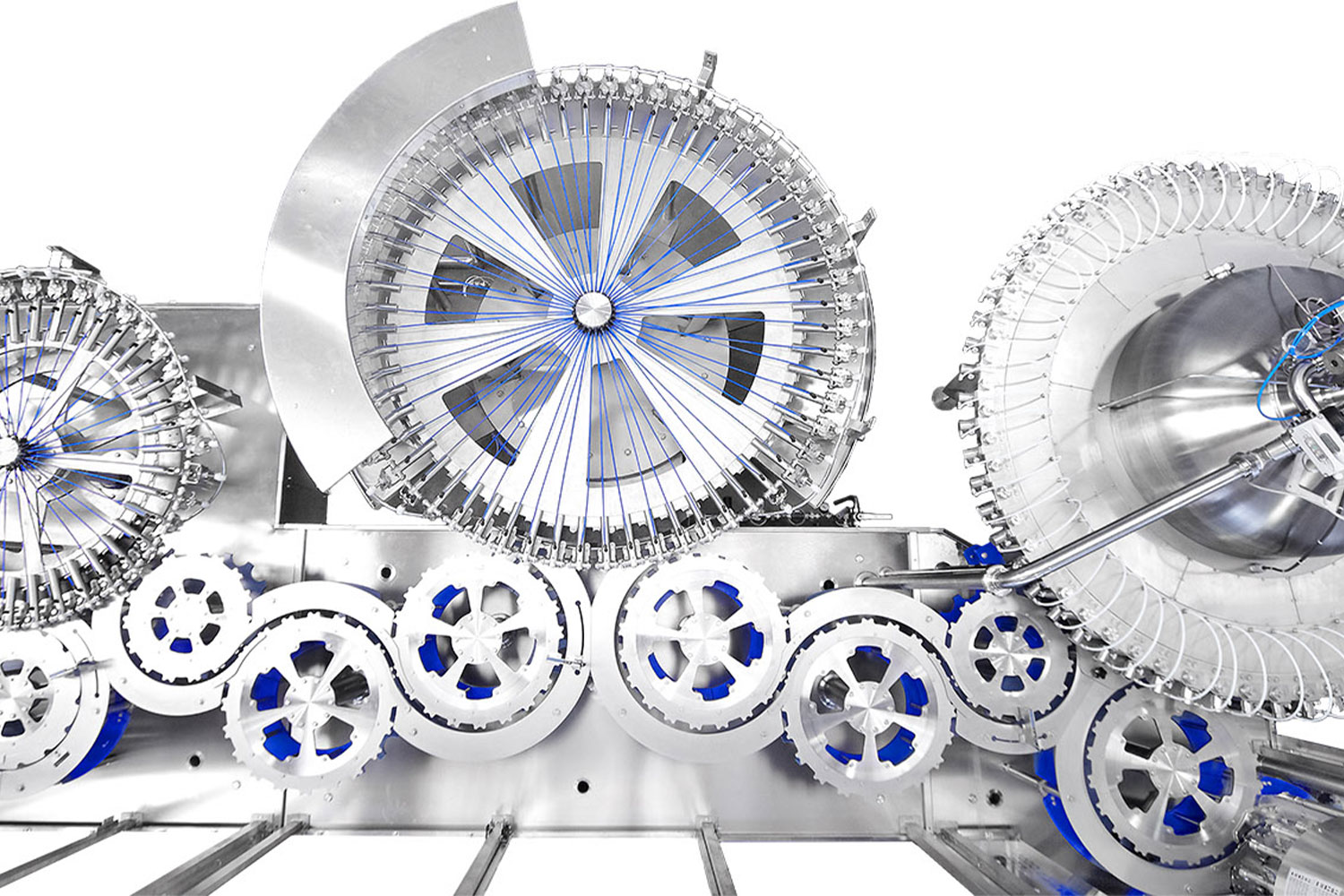

VOLJET H is our volumetric filler model suitable for filling “hot” products such as juices with and without pulps or fibers, tea and isotonic drinks. Thanks to filling temperatures up to 90 ° C, depending on the characteristics of the container, it is used for medium and long-term storage at room temperature. It is equipped with flow meters, one for each filling valve, and can handle all types of containers without any contact between the bottle and the valve itself, thus avoiding any vertical movement. Each filling tap is equipped with an auxiliary pneumatic membrane valve that allows the product to be recirculated inside the valve, thus meeting the quality required by international standards. Other particularities:

– Absence of the bottle lifting jack

– Absence of dynamic seals

– Very low need for maintenance interventions

– High hygiene guarantees thanks to the lack of contact between valve and bottle

– Extremely effective sanitization process.

ADVANTAGES

- High content accuracy

- Independent monitoring of each single filling valve through dedicated product recipes.

- Active control of performances with the possibility of acting on each valve.

- Extremely simple to use thanks to the touch screen operator panel

- The “double speed” option also grants product smooth filling without turbulence

- Electro-pneumatic control of all machine functions

- In case of prolonged machine stop, the product is automatically recycled through the membrane valve, to keep constant the temperature of the whole circuit

FRUIT JUICE, TEA, SPORTS DRINKS

- Production: 4.000 ÷ 60.000 bph

- n ° valves: 12 ÷ 140

- PET treatable bottles

- Treatable bottles (h) 140 ÷ 340

- Treatable bottles (Ø) 48 ÷ 115

- Parts in contact with the product in SS 304

- Touch Screen operator panel

- Laminar flow cabin with positive pressure and HEPA filters

- Double filling speed to grant the absence of turbulence

- Dummy bottles for sanitation with manual insertion

- Dummy bottles for sanitation with automatic insertion

- Base in SS 304

- SS 304 and Drainable base

- Automatic centralized lubrication

- Parts in contact with the product in SS 316L

- Remote assistance

Each filling valve is controlled by individual flow meter through which the volume of product to be filled into the bottle is dosed with extreme precision. Upon reaching the set volume, according to the recipe of the format in use, the filling cycle stops. With the “double speed” filling option, the filling of sensitive products is smooth and without turbulence.

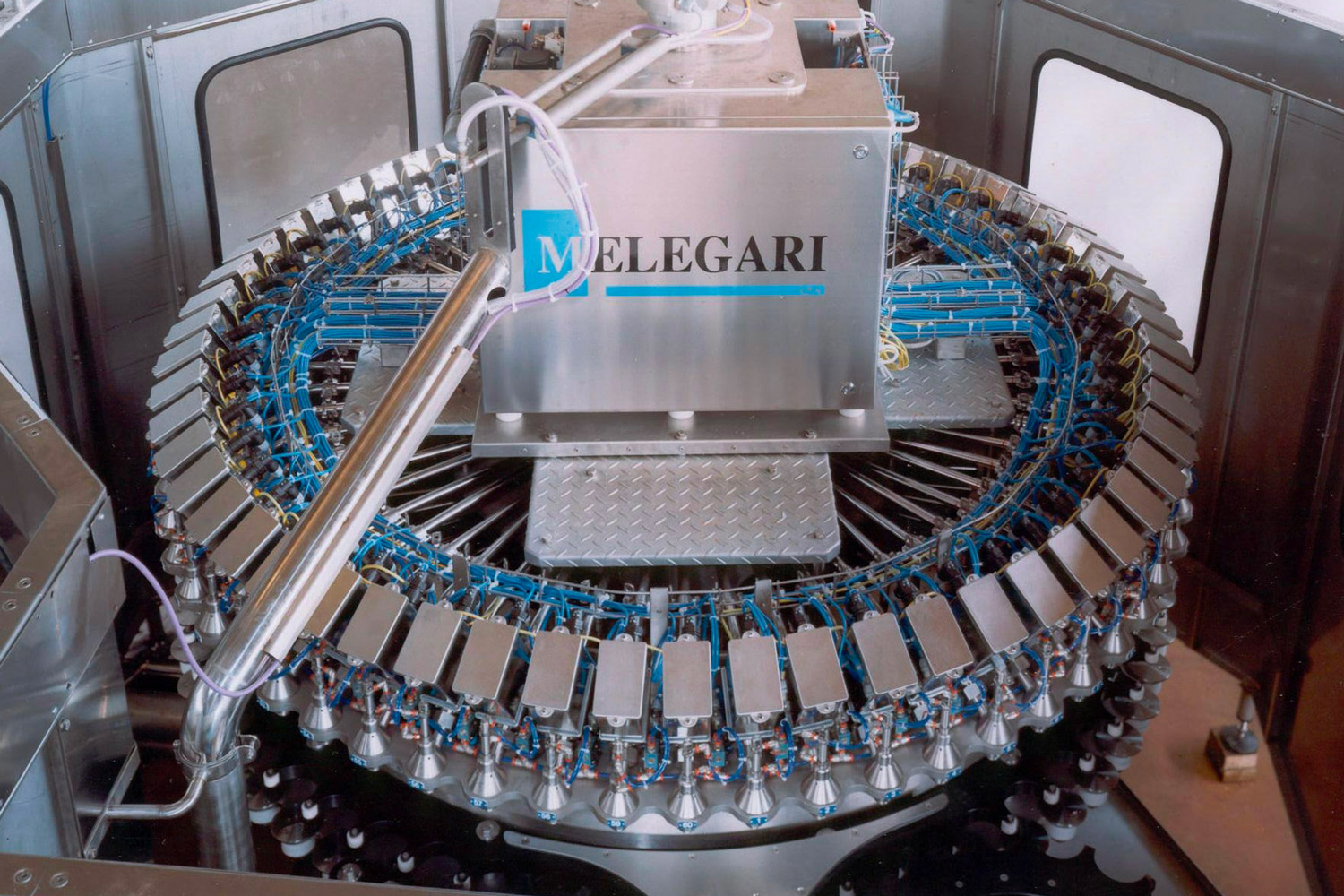

All machine cycles are electro-pneumatically controlled

The Cip, carried on in closed circuit through the insertion of dummy bottles (optionally also with automatic control), is made automatically and can be set from the operator panel. To facilitate washing and drainage, all surfaces in contact with the product are slightly inclined and mirror polished.

Fill in the form to receive all the details you need about all Melegari Technology bottling machinery

Discover more products of

Promec Group

Leader in bottle handling, cleaning and sterilization sector.

Promec srl

New intelligent blow molding machines, for a sustainable choice.

Blowtec